Special Price for Sand Casting Iron Foundry - Valver bonnet – Yogem

Special Price for Sand Casting Iron Foundry - Valver bonnet – Yogem Detail:

Gray iron is the most versatile of all foundry metals. The high carbon content is responsible for ease of melting and casting in the foundry and for ease of machining in subsequent manufacturing. The low degree or absence of shrinkage and high fluidity provide maximum freedom of design for the engineer.

The general composition of gray cast iron is 95% iron by weight with an additional 2.1 to 4% being carbon and 1 to 3% silicon. Manganese and other impurities are also commonly found in or added to molten iron as needed for the diminishing or enhancement of specific properties. Sulfur, for example, is commonly introduced to the molten metal in order to increase hardness, which is otherwise low in most cast iron components.

Green sand molding is frequently the most economical method of producing castings. Although castings up to 500kgs pounds or more can be made in green sand, it generally is used for medium to small size castings. If green sand molds are not sufficiently hard or strong, some mold wall movement may take place during solidification, and shrinkage defects develop.

The shell molding process is also used for making cores, which are used in other types of molds besides shell molds. The primary advantage is the ability to harden the mold or core in contact with a heated metal pattern, improving the accuracy and finish of the casting.

Gray iron casting is used in many market segments, including automotive, agricultural, machinery building, electronics, irrigation, ventilation, architecture, construction and transportation industries

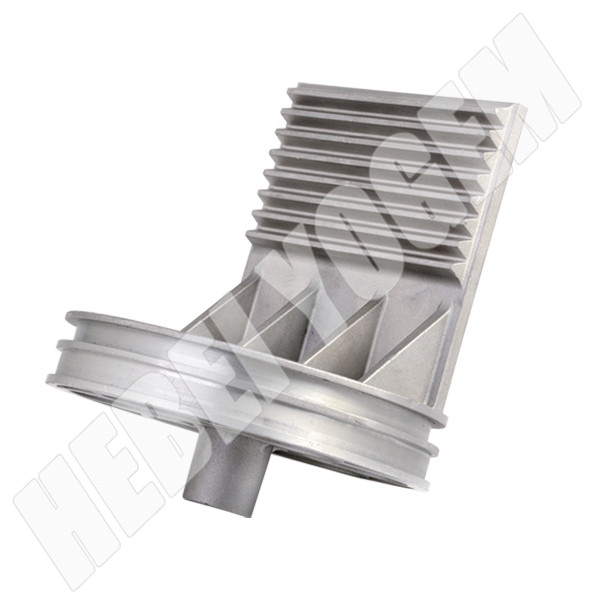

Product detail pictures:

Related Product Guide:

General Building Codes Approval â MHS Structural Aluminum Framing (LARR 25703) | Aluminum Extrusion Housing

Local construction industry likely to feel pinch of global aluminium price surge – Daily Mirror | Precision Aluminum Parts

We are also focusing on enhancing the things administration and QC program in order that we could keep fantastic advantage within the fiercely-competitive enterprise for Special Price for Sand Casting Iron Foundry - Valver bonnet – Yogem, The product will supply to all over the world, such as: Hongkong , Hamburg , Italy , Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!