Rapid Delivery for Investment Casting Brass - Power accessory – Yogem

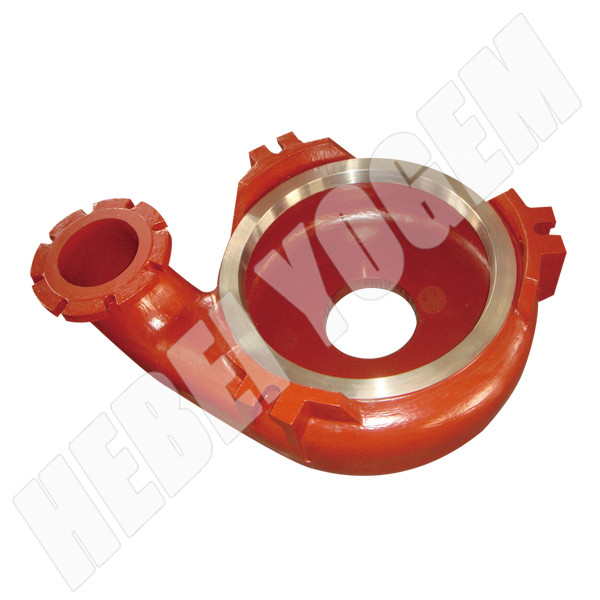

Rapid Delivery for Investment Casting Brass - Power accessory – Yogem Detail:

Weight scope:0.1-50kg

technology:Sand casting, die casting, gravity casting, investment casting

application:Pump, valve, automobile, agriculture, other mechanical field.

Aluminum casting

Aluminum castings are formed by pouring molten metal into molds which have been shaped by a pattern of the desired product. Three common types of molding methods are used to produce aluminum castings:

Die casting

Die casting uses pressure to force molten aluminum into a steel die (mold). This type of casting is often used for mass production of parts, which require a minimum amount of finishing and machining. Die casting has short cycle times but high costs for tooling. The pressurized casting system creates a high strength skin but weaker interior than permanent mold casting.

Permanent mold casting

Permanent mold casting uses steel (or other metal) molds and cores. Strong castings are formed by pouring aluminum into the mold. Permanent molds are used to create highly repeatable parts with consistency. Their rapid cooling rates generate a more consistent microstructure, which can improve the mechanical properties significantly.

Sand casting

Sand castings are created by packing a fine sand mixture around a pattern of the desired product. The pattern is slightly larger than the final product to allow for shrinkage of the aluminum while cooling. Sand casting is economical because the sand is reused multiple times over. It is also effective for creating large moldings or moldings with detailed designs. Upfront tooling costs are low but per part prices are higher, making sand casting more suitable for specialized castings than mass production.

Product detail pictures:

Related Product Guide:

Staff from Bahrain’s Alba complete Line 6 training with UAE’s EGA – Projects & Tenders | Copper Base Alloy

ASIA COPPER WEEK 2018: China’s supply of copper scrap in 2019 not a cause for concern | Thailand Aluminium Casting

We are experienced manufacturer. Wining the majority from the crucial certifications of its market for Rapid Delivery for Investment Casting Brass - Power accessory – Yogem, The product will supply to all over the world, such as: Oslo , Canada , Saudi Arabia , We take measure at any price to attain essentially the most up-to-date gear and procedures. The packing of nominated brand is our a further distinguishing feature. The solutions to assure years of trouble-free service has attracted a great deal customers. The goods are obtainable in improved designs and richer variety, they're produced scientifically of purely raw supplies. It accessible in a variety of designs and specifications for the selection. The newest forms are much far better than the previous one and they're extremely popular with several clients.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!