Rapid Delivery for Investment Casting Brass - Pneumatic valve piston – Yogem

Rapid Delivery for Investment Casting Brass - Pneumatic valve piston – Yogem Detail:

Weight scope:0.1-50kg

technology:Sand casting, die casting, gravity casting, investment casting

application:Pump, valve, automobile, agriculture, other mechanical field.

Aluminum casting

Aluminum castings are formed by pouring molten metal into molds which have been shaped by a pattern of the desired product. Three common types of molding methods are used to produce aluminum castings:

Die casting

Die casting uses pressure to force molten aluminum into a steel die (mold). This type of casting is often used for mass production of parts, which require a minimum amount of finishing and machining. Die casting has short cycle times but high costs for tooling. The pressurized casting system creates a high strength skin but weaker interior than permanent mold casting.

Permanent mold casting

Permanent mold casting uses steel (or other metal) molds and cores. Strong castings are formed by pouring aluminum into the mold. Permanent molds are used to create highly repeatable parts with consistency. Their rapid cooling rates generate a more consistent microstructure, which can improve the mechanical properties significantly.

Sand casting

Sand castings are created by packing a fine sand mixture around a pattern of the desired product. The pattern is slightly larger than the final product to allow for shrinkage of the aluminum while cooling. Sand casting is economical because the sand is reused multiple times over. It is also effective for creating large moldings or moldings with detailed designs. Upfront tooling costs are low but per part prices are higher, making sand casting more suitable for specialized castings than mass production.

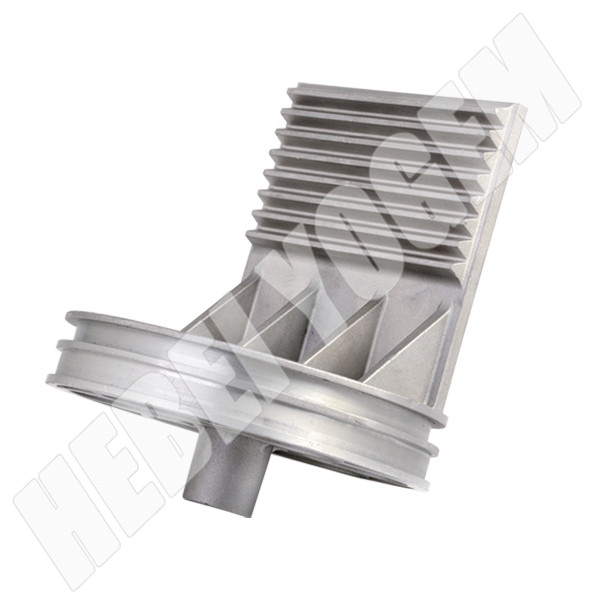

Product detail pictures:

Related Product Guide:

Nissan casting plant celebrates 35 years in Oz | foundry-planet.com | Centrifugal Slurry Pump

Mid-April Metals Analysis: Aluminum, Copper and Nickel Prices Rise, Other Base Metals Fall | Aluminum Extrusion Housing

continue on to further improve, to make sure product top quality in line with market and consumer standard requirements. Our firm has a excellent assurance program have already been established for Rapid Delivery for Investment Casting Brass - Pneumatic valve piston – Yogem, The product will supply to all over the world, such as: Kuwait , United States , Denver , They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a should for you of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we are going to possess a vibrant prospect and to be distributed all over the world within the years to come.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!