OEM manufacturer Cnc Machinery Engine Parts - Reducer box – Yogem

OEM manufacturer Cnc Machinery Engine Parts - Reducer box – Yogem Detail:

Gray iron is the most versatile of all foundry metals. The high carbon content is responsible for ease of melting and casting in the foundry and for ease of machining in subsequent manufacturing. The low degree or absence of shrinkage and high fluidity provide maximum freedom of design for the engineer.

The general composition of gray cast iron is 95% iron by weight with an additional 2.1 to 4% being carbon and 1 to 3% silicon. Manganese and other impurities are also commonly found in or added to molten iron as needed for the diminishing or enhancement of specific properties. Sulfur, for example, is commonly introduced to the molten metal in order to increase hardness, which is otherwise low in most cast iron components.

Green sand molding is frequently the most economical method of producing castings. Although castings up to 500kgs pounds or more can be made in green sand, it generally is used for medium to small size castings. If green sand molds are not sufficiently hard or strong, some mold wall movement may take place during solidification, and shrinkage defects develop.

The shell molding process is also used for making cores, which are used in other types of molds besides shell molds. The primary advantage is the ability to harden the mold or core in contact with a heated metal pattern, improving the accuracy and finish of the casting.

Gray iron casting is used in many market segments, including automotive, agricultural, machinery building, electronics, irrigation, ventilation, architecture, construction and transportation industries

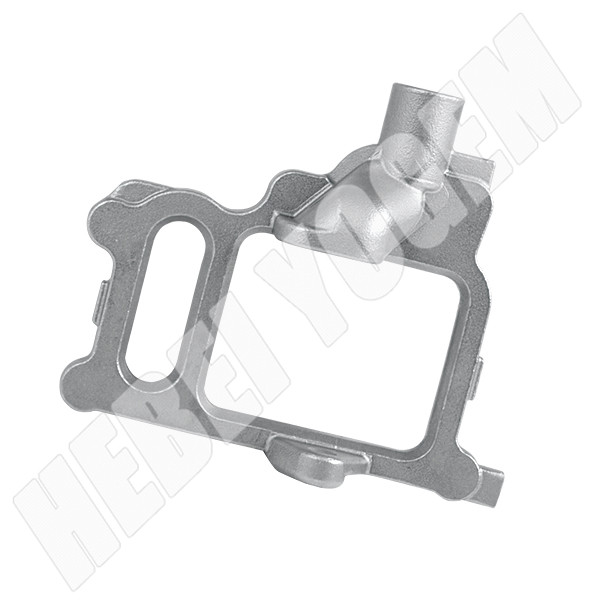

Product detail pictures:

Related Product Guide:

Integrated Pump Rental adds submersible pumps to its rental fleet | Precision Aluminum Parts

UK steps into G7 trade dispute, warns of tit-for-tat dangers | Copper Base Alloy

To be a result of ours specialty and repair consciousness, our corporation has won an excellent reputation amongst customers all around the entire world for OEM manufacturer Cnc Machinery Engine Parts - Reducer box – Yogem, The product will supply to all over the world, such as: Sevilla , Kenya , Ottawa , Adhering to the management tenet of "Managing Sincerely, Winning by Quality", we try our best to provide excellent products and service to our clients. We look forward to making progress together with domestic and international clients.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.