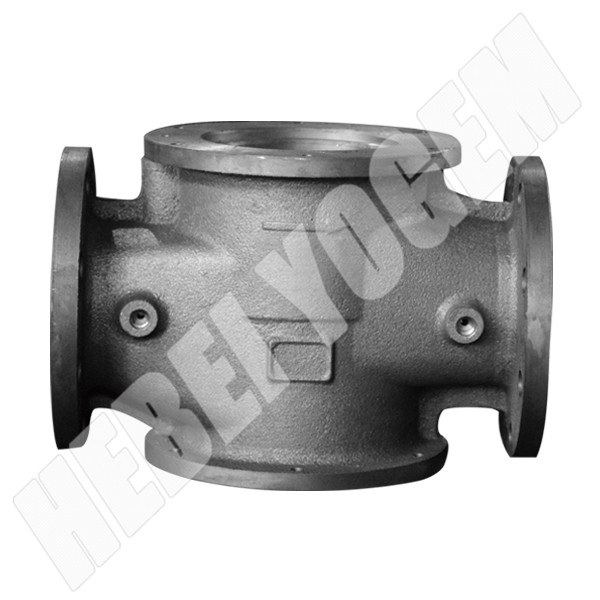

Factory making Ectfe F30 Coating - Pump cover – Yogem

Factory making Ectfe F30 Coating - Pump cover – Yogem Detail:

Gray iron is the most versatile of all foundry metals. The high carbon content is responsible for ease of melting and casting in the foundry and for ease of machining in subsequent manufacturing. The low degree or absence of shrinkage and high fluidity provide maximum freedom of design for the engineer.

The general composition of gray cast iron is 95% iron by weight with an additional 2.1 to 4% being carbon and 1 to 3% silicon. Manganese and other impurities are also commonly found in or added to molten iron as needed for the diminishing or enhancement of specific properties. Sulfur, for example, is commonly introduced to the molten metal in order to increase hardness, which is otherwise low in most cast iron components.

Green sand molding is frequently the most economical method of producing castings. Although castings up to 500kgs pounds or more can be made in green sand, it generally is used for medium to small size castings. If green sand molds are not sufficiently hard or strong, some mold wall movement may take place during solidification, and shrinkage defects develop.

The shell molding process is also used for making cores, which are used in other types of molds besides shell molds. The primary advantage is the ability to harden the mold or core in contact with a heated metal pattern, improving the accuracy and finish of the casting.

Gray iron casting is used in many market segments, including automotive, agricultural, machinery building, electronics, irrigation, ventilation, architecture, construction and transportation industries

Product detail pictures:

Related Product Guide:

NYSE:BRSS | Thailand Aluminium Casting

General Building Codes Approval â MHS Structural Aluminum Framing (LARR 25703) | Centrifugal Slurry Pump

We always believe that one's character decides products' quality, the details decides products' quality ,with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for Factory making Ectfe F30 Coating - Pump cover – Yogem, The product will supply to all over the world, such as: Ghana , moldova , moldova , With its rich manufacturing experience, high-quality products, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing series.We sincerely hope to establish business relation with you and pursue mutual benefit.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.