Factory best selling 200mm Ductile Iron Pipes - Valve body – Yogem

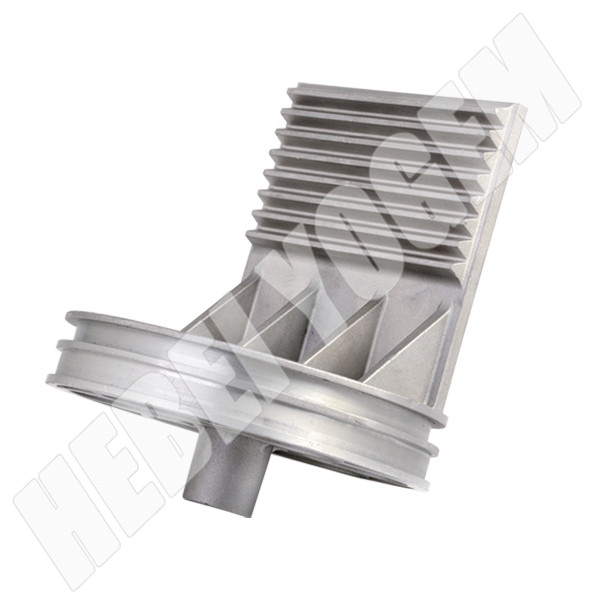

Factory best selling 200mm Ductile Iron Pipes - Valve body – Yogem Detail:

Weight scope:0.1-50kg

technology:Sand casting, die casting, gravity casting, investment casting

application:Pump, valve, automobile, agriculture, other mechanical field.

Aluminum casting

Aluminum castings are formed by pouring molten metal into molds which have been shaped by a pattern of the desired product. Three common types of molding methods are used to produce aluminum castings:

Die casting

Die casting uses pressure to force molten aluminum into a steel die (mold). This type of casting is often used for mass production of parts, which require a minimum amount of finishing and machining. Die casting has short cycle times but high costs for tooling. The pressurized casting system creates a high strength skin but weaker interior than permanent mold casting.

Permanent mold casting

Permanent mold casting uses steel (or other metal) molds and cores. Strong castings are formed by pouring aluminum into the mold. Permanent molds are used to create highly repeatable parts with consistency. Their rapid cooling rates generate a more consistent microstructure, which can improve the mechanical properties significantly.

Sand casting

Sand castings are created by packing a fine sand mixture around a pattern of the desired product. The pattern is slightly larger than the final product to allow for shrinkage of the aluminum while cooling. Sand casting is economical because the sand is reused multiple times over. It is also effective for creating large moldings or moldings with detailed designs. Upfront tooling costs are low but per part prices are higher, making sand casting more suitable for specialized castings than mass production.

Product detail pictures:

Related Product Guide:

FOCUS: Trade tensions trump strong fundamentals amid diving copper price | Centrifugal Slurry Pump

ASIAN MORNING BRIEF 27/06: Base metals volatility continues; trade war threat weighs on Comex copper price; MB holds month-long consultation on MJP aluminium premium | Aluminum Extrusion Housing

Our development depends on the advanced equipment ,excellent talents and continuously strengthened technology forces for Factory best selling 200mm Ductile Iron Pipes - Valve body – Yogem, The product will supply to all over the world, such as: Spain , US , Morocco , We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy you with our high-quality products and solutions and perfect service . We also warmly welcome customers to visit our company and purchase our products.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.