Competitive Price for Squeeze Casting - Reducer housing – Yogem

Competitive Price for Squeeze Casting - Reducer housing – Yogem Detail:

Gray iron is the most versatile of all foundry metals. The high carbon content is responsible for ease of melting and casting in the foundry and for ease of machining in subsequent manufacturing. The low degree or absence of shrinkage and high fluidity provide maximum freedom of design for the engineer.

The general composition of gray cast iron is 95% iron by weight with an additional 2.1 to 4% being carbon and 1 to 3% silicon. Manganese and other impurities are also commonly found in or added to molten iron as needed for the diminishing or enhancement of specific properties. Sulfur, for example, is commonly introduced to the molten metal in order to increase hardness, which is otherwise low in most cast iron components.

Green sand molding is frequently the most economical method of producing castings. Although castings up to 500kgs pounds or more can be made in green sand, it generally is used for medium to small size castings. If green sand molds are not sufficiently hard or strong, some mold wall movement may take place during solidification, and shrinkage defects develop.

The shell molding process is also used for making cores, which are used in other types of molds besides shell molds. The primary advantage is the ability to harden the mold or core in contact with a heated metal pattern, improving the accuracy and finish of the casting.

Gray iron casting is used in many market segments, including automotive, agricultural, machinery building, electronics, irrigation, ventilation, architecture, construction and transportation industries

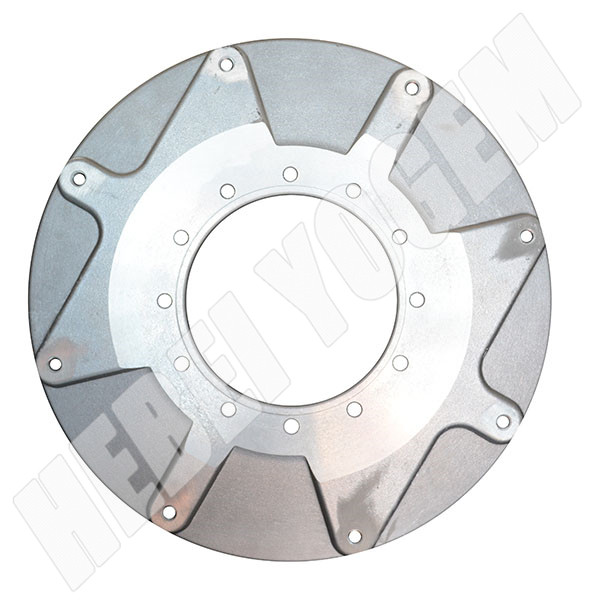

Product detail pictures:

Related Product Guide:

Centrifugal Slurry Pumps Market Data- Product Costs, Revenue, Margins and Market Share, Forecast till 2025 | Centrifugal Slurry Pump

Youngstown Tool & Die to spend at least $13 million on project | Copper Base Alloy

To be the stage of realizing dreams of our employees! To build a happier, far more united and far more specialist team! To reach a mutual profit of our customers, suppliers, the society and ourselves for Competitive Price for Squeeze Casting - Reducer housing – Yogem, The product will supply to all over the world, such as: Mexico , Lithuania , United States , Our products and solutions are sold to the Middle East, Southeast Asia, Africa, Europe, America and other regions, and are favorably appraised by clients. To benefit from our strong OEM/ODM capabilities and considerate services, be sure to contact us today. We will sincerely create and share success with all clients.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.