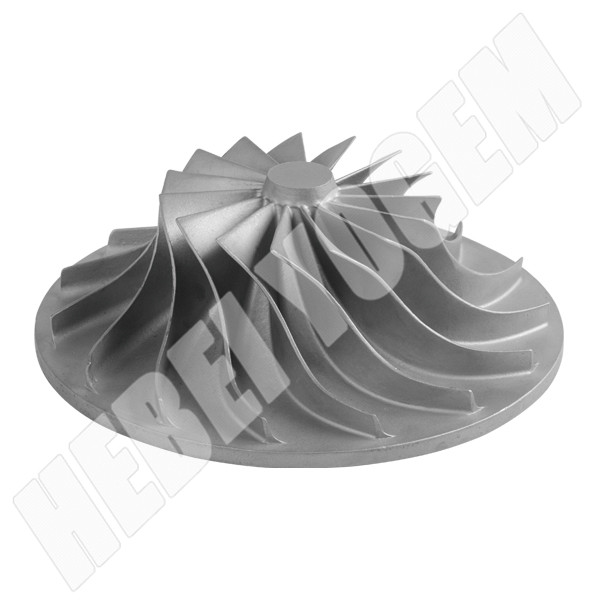

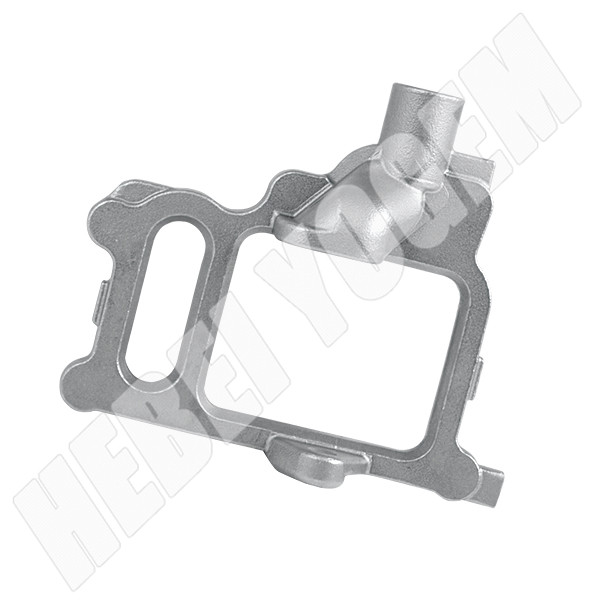

China wholesale Pump Shell Part - Power accessory – Yogem

China wholesale Pump Shell Part - Power accessory – Yogem Detail:

Weight scope:0.1-50kg

technology:Sand casting, die casting, gravity casting, investment casting

application:Pump, valve, automobile, agriculture, other mechanical field.

Aluminum casting

Aluminum castings are formed by pouring molten metal into molds which have been shaped by a pattern of the desired product. Three common types of molding methods are used to produce aluminum castings:

Die casting

Die casting uses pressure to force molten aluminum into a steel die (mold). This type of casting is often used for mass production of parts, which require a minimum amount of finishing and machining. Die casting has short cycle times but high costs for tooling. The pressurized casting system creates a high strength skin but weaker interior than permanent mold casting.

Permanent mold casting

Permanent mold casting uses steel (or other metal) molds and cores. Strong castings are formed by pouring aluminum into the mold. Permanent molds are used to create highly repeatable parts with consistency. Their rapid cooling rates generate a more consistent microstructure, which can improve the mechanical properties significantly.

Sand casting

Sand castings are created by packing a fine sand mixture around a pattern of the desired product. The pattern is slightly larger than the final product to allow for shrinkage of the aluminum while cooling. Sand casting is economical because the sand is reused multiple times over. It is also effective for creating large moldings or moldings with detailed designs. Upfront tooling costs are low but per part prices are higher, making sand casting more suitable for specialized castings than mass production.

Product detail pictures:

Related Product Guide:

Isuzu launches standalone South African business, new mu-X utility vehicle | Aluminum Extrusion Housing

GreenLux LED releases aluminum recessed extrusions for linear LED lighting applications | Precision Aluminum Parts

Well-run products, skilled income group, and better after-sales products and services; We have been also a unified massive family, all people stick with the business price "unification, dedication, tolerance" for China wholesale Pump Shell Part - Power accessory – Yogem, The product will supply to all over the world, such as: Las Vegas , Thailand , Angola , Due to our strict pursues in quality, and after-sale service, our product gets more and more popular around the world. Many clients came to visit our factory and place orders. And there are also many foreign friends who came for sight seeing, or entrust us to buy other stuff for them. You are most welcome to come to China, to our city and to our factory!

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!